QLECTOR d.o.o.

Qlector – Transform Your Manufacturing Process with AI

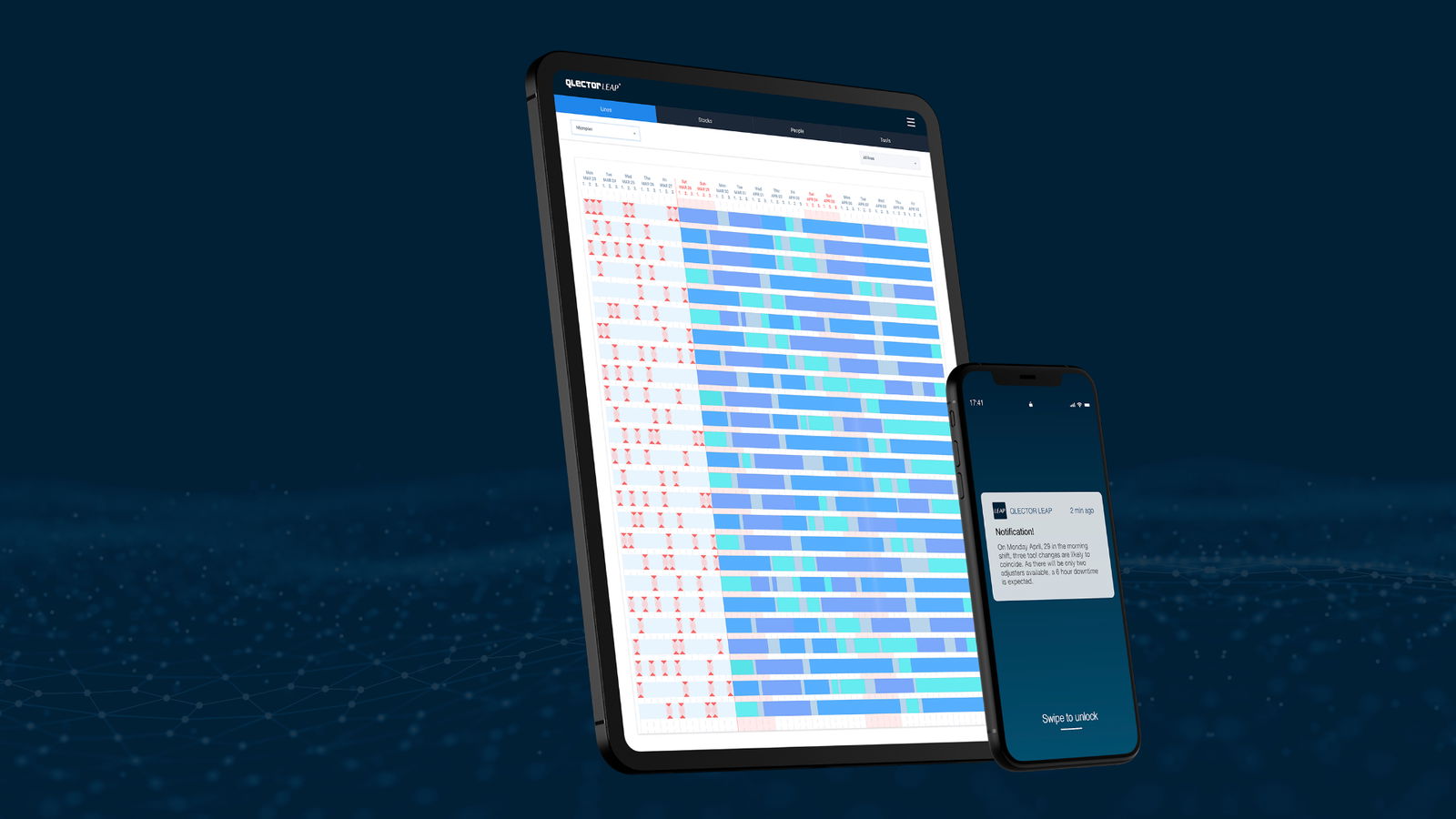

Qlector LEAP is a groundbreaking manufacturing solution that harnesses the power of machine learning to create a self-learning digital twin. This innovative technology provides manufacturers with in-depth insights, accurate forecasting capabilities, and advanced optimization of production processes.

Empower Your Facility

Experience a significant increase in planner productivity, reduced inventory levels, and enhanced on-time delivery. Qlector LEAP allows manufacturers to plan smarter, leading to optimized workflows and efficient resource management.

Key Benefits of Qlector LEAP

| Benefit | Percentage Improvement |

|---|---|

| Increased planner productivity | 50% |

| Increased on-time delivery | 30% |

| Reduced organizational downtime | 25% |

| Shortened production time | 10% |

| Time savings for logistics personnel | 15% (8 hours/week) |

| Reduced inventory levels | 2.5% |

| Reduced work-in-progress (WIP) | 20% |

Modular AI Solution

Qlector LEAP is built on a modular framework that includes three core modules: Digital Twin, Product Guiding, and Production Optimization. These components work together to provide a comprehensive solution for modern manufacturing challenges by enhancing prediction accuracy and optimizing decision-making processes.

Real-world Impact

Our customers, including prominent companies like Kovis, Kolektor, ams OSRAM, and Domel, have praised Qlector LEAP for its ability to streamline production planning and improve operational efficiency. With its user-friendly interface and robust real-time updates, it is transforming how production managers and planners operate daily.

Ready to Optimize Your Production?

Contact our expert team to explore how Qlector LEAP can address your planning challenges and bring efficiency to your shop floor. Witness firsthand how this innovative solution can reshape your manufacturing processes for the better.

- Parkiralište pristupačno za invalidska kolica: Da

- Potreban termin: Da

- ponedjeljak 8 do 16 sati

- utorak 8 do 16 sati

- srijeda 8 do 16 sati

- četvrtak 8 do 16 sati

- petak 8 do 16 sati

- subota Zatvoreno

- nedjelja Zatvoreno